Who We Are

FPI AUTO PARTS INDIA

Fortune Parts Industry (FPI) is an Automotive Manufacturer, and we provide One Stop Service for Automotive Manufacturing Services. We started as an automotive replacement parts manufacturing with substantial experiences in automotive field. We continued to expand the production base to the body parts factory which is a vertically integrated company with world-class factory standards. Our services include Molding, Painting, Assembly and Design Centre.

With 30 years experience of experience, professional expertise, a strong client base, and the use of advance technology, FPI is able to improve our products and services and exceed customer requirements and needs. Being a leader in the automotive, we understand that the best quality of products and services begins with high quality materials, highly skilled staffs, and the use of advanced technology. Automotive Manufacturer Automotive Manufacturer Automotive Manufacturer Automotive Manufacturer Automotive Manufacturer

Our Services

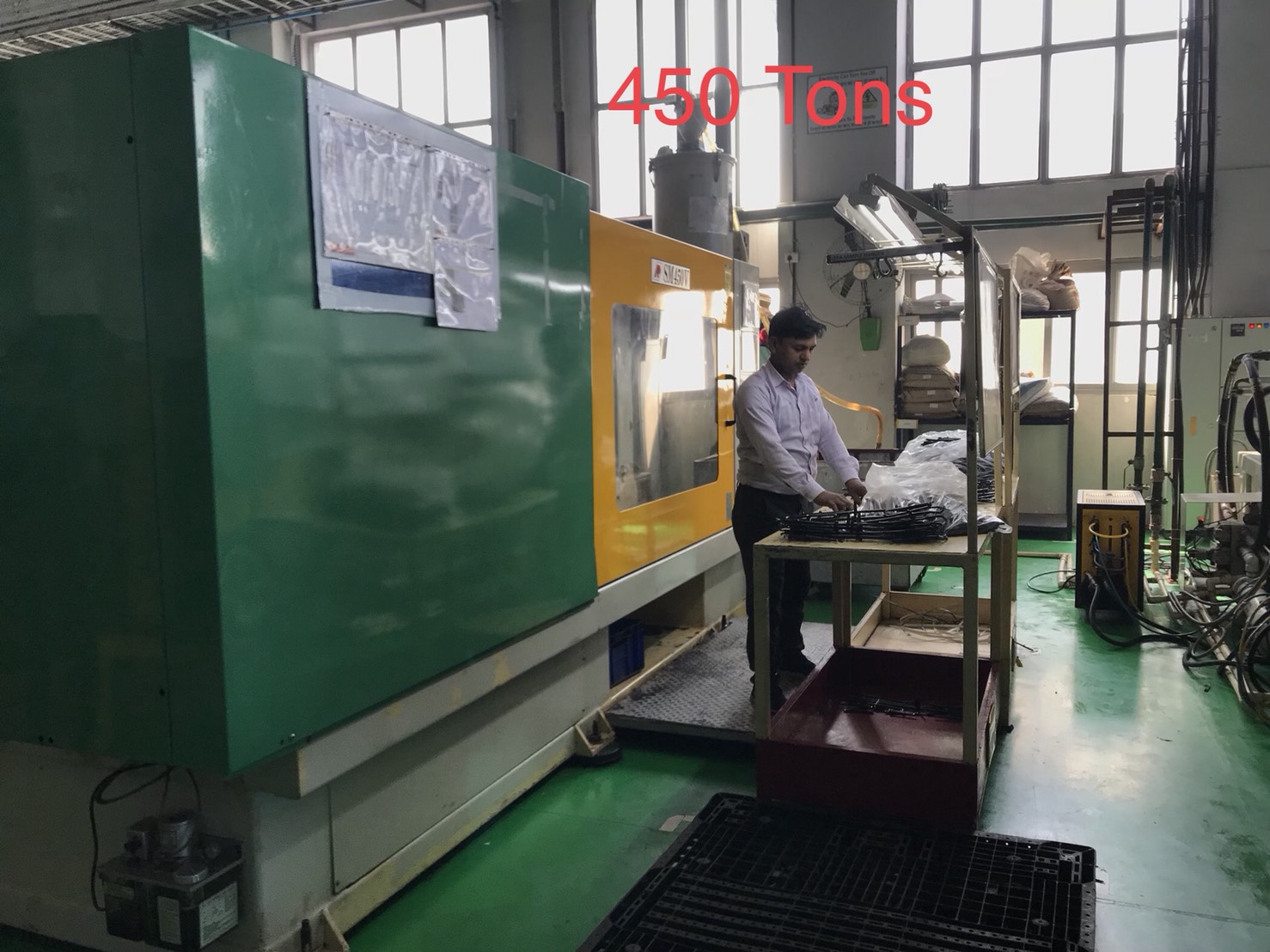

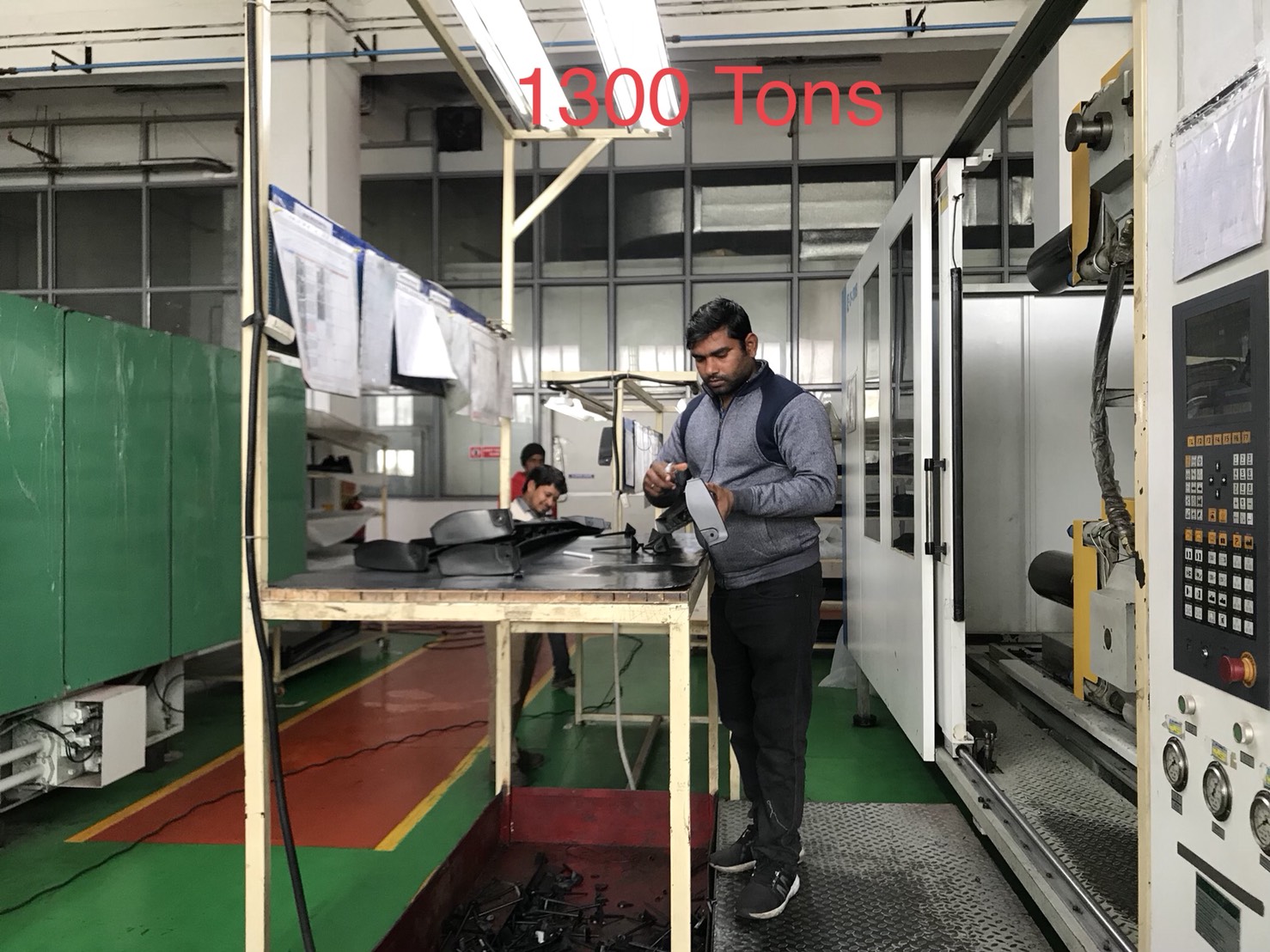

FPI molding section is equipped with different range of machines, which are able to cater to customer's versatile range of product demand. The capacity of molding machine is 350 to 2,000 tons. We have the knowledge, experience, and facilities to build products that meet the unique needs of customers in virtually every industry. We understand the unique needs of many industries and are able to combine that collective experience and knowledge to offer customers solutions at the highest levels. FPI molding section is headed by well experienced and groomed staff to provide cost effective solutions to customers.

FPI molding section is equipped with different range of machines, which are able to cater to customer's versatile range of product demand. The capacity of molding machine is 350 to 2,000 tons. We have the knowledge, experience, and facilities to build products that meet the unique needs of customers in virtually every industry. We understand the unique needs of many industries and are able to combine that collective experience and knowledge to offer customers solutions at the highest levels. FPI molding section is headed by well experienced and groomed staff to provide cost effective solutions to customers.

FPI molding section is equipped with different range of machines, which are able to cater to customer's versatile range of product demand. The capacity of injection molding machine is 350 to 2,000 tons. We have the knowledge, experience, and facilities to build products that meet the unique needs of customers in virtually every industry. We understand the unique needs of many industries and are able to combine that collective experience and knowledge to offer customers solutions at the highest levels. FPI molding section is headed by well experienced and groomed staff to provide cost effective solutions to customers.

Painting section has flexible painting line which provides cost effective solutions and maintain the international quality standards, which results in a very low rejection rate. The painting facilities is semi auto spray painting with conveyor type paint baking oven and the specification of L = 12000 x W = 4000 x H = 4000 mm. The maximum capacity is 3,500 pcs/day (part size 1800 x 400 x 50 mm). Additionally, our team is headed by professionals, who can effectively handle all types of customer painting requirement s like dual color, special effect etc. We are committed to meet the specific need of the customers.

Painting section has flexible painting line which provides cost effective solutions and maintain the international quality standards, which results in a very low rejection rate. The painting facilities is semi auto spray painting with conveyor type paint baking oven and the specification of L = 12000 x W = 4000 x H = 4000 mm. The maximum capacity is 3,500 pcs/day (part size 1800 x 400 x 50 mm). Additionally, our team is headed by professionals, who can effectively handle all types of customer painting requirement s like dual color, special effect etc. We are committed to meet the specific need of the customers.

Painting section has flexible painting line which provides cost effective solutions and maintain the international quality standards, which results in a very low rejection rate. The painting facilities is semi auto spray painting with conveyor type paint baking oven and the specification of L = 12000 x W = 4000 x H = 4000 mm. The maximum capacity is 3,500 pcs/day (part size 1800 x 400 x 50 mm). Additionally, our team is headed by professionals, who can effectively handle all types of customer painting requirement s like dual color, special effect etc. We are committed to meet the specific need of the customers.

Assembly line is based on flexible manufacturing system, which we are able to meet customer demand. There are 6 assembly lines with the specification of L = 6000 x W = 1000 x H = 2000 mm. Moreover, it is quipped with world class equipment. It focuses on lean manufacturing system, line balancing, fool proofing by implementing poka yoke system and already in process of industry 4.0.

Assembly line is based on flexible manufacturing system, which we are able to meet customer demand. There are 6 assembly lines with the specification of L = 6000 x W = 1000 x H = 2000 mm. Moreover, it is quipped with world class equipment. It focuses on lean manufacturing system, line balancing, fool proofing by implementing poka yoke system and already in process of industry 4.0.

Assembly line is based on flexible manufacturing system, which we are able to meet customer demand. There are 6 assembly lines with the specification of L = 6000 x W = 1000 x H = 2000 mm. Moreover, it is quipped with world class equipment. It focuses on lean manufacturing system, line balancing, fool proofing by implementing poka yoke system and already in process of industry 4.0.

Assembly line is based on flexible manufacturing system, which we are able to meet customer demand. There are 6 assembly lines with the specification of L = 6000 x W = 1000 x H = 2000 mm. Moreover, it is quipped with world class equipment. It focuses on lean manufacturing system, line balancing, fool proofing by implementing poka yoke system and already in process of industry 4.0.

Assembly line is based on flexible manufacturing system, which we are able to meet customer demand. There are 6 assembly lines with the specification of L = 6000 x W = 1000 x H = 2000 mm. Moreover, it is quipped with world class equipment. It focuses on lean manufacturing system, line balancing, fool proofing by implementing poka yoke system and already in process of industry 4.0.

Our in-house design facility provides the best and cost effective solutions to customers. Our design team consists of talented engineers with leading CAD/CAM capabilities, which offer non-stop service like design feasibility study, product designing, mold-flow, try-outs etc. Our Design Centre is well equipped with all the latest versions of software and simulators that provide the best designing solution to customers.

FPI AUTO PARTS INDIA PRIVATE LIMITED

On the whole, we can say that FPI India is one roof solutions for customer where we can provide from start to end. It always focuses on customer requirement and it is able to provide best solutions to customer within a designated time frame. We are very strong in 'New Product Design' and we can handle different projects at a time. Advantageously, we have a great technical support from our mother plant FPI Thailand.

International Standards

Certification of Registration

-

- IATF 16949: 2016 | Organization’s Quality Management System

- ISO 14001: 2015 | Organization’s Environmental Management System

- ISO 9001: 2015 | Organization’s Quality Management System

In-House Quality Assurance Equipment

-

MATERIAL FLOW TESTER

-

SALT SPRAY & WARM WATER TESTING CHAMBER

-

HUMIDITY CHAMBER

-

HEATING & COOLING OVEN

-

DUST PARTICLE COUNTER

-

METAL & PENCIL HARDNESS TESTER

-

IMPACT & DENSITY TESTER

-

AIR VELOCITY, DFT, GLOSS, CHROMA, AND LUX METER

-

DIGITAL VERNIER CALIPER

-

MICROMETER

Automotive Manufacture Automotive Manufacturer Automotive Manufacturerr utomotive Manufacturerr